"Most E&C companies continue to face sustained cost and margin pressures. Additionally, despite strong order books, companies are experiencing challenges such as project delays and cancellations and difficulty in obtaining permits. In

addition, increases in procurement cost of materials and equipment continue to perplex many E&C companies. But there are reasons to be optimistic. Connected technologies and an increase in associated investments may help firms realize new operational efficiencies."

Deloitte, Engineering and Construction Industry Outlook, 2021

Real estate development experienced severe setbacks in recent years. Like most major industries, construction faced COVID-19 shocks, labor shortages, supply chain issues and pronounced inflation. However, despite the financial losses, vast advances in smart construction technologies are expected to help the entire engineering and construction industry experience a type of renaissance, provoking a digital transformation across construction.

In response, Modern Methods of Construction (MMC) was recently published by the MHCLG Joint Industry Working Group. Designed with vast input from builders and construction organizations across England, the MMC is a codified, definitional framework for all future construction projects, allowing buildings to be "future-proofed."

As a framework, Modern Methods of Construction offers definitional categories and subcategories for smart industrialized construction. This framework is based almost entirely on finding efficiencies and cost savings in construction, such as in modular construction and the off-site prefabrication of building materials.

MMC: An Introduction & Overview

"E&C companies should consider several ways to create long-term efficiencies... One option is to save costs via modularization and prefabrication design. Twenty-six percent of E&C executives in a Deloitte postelection poll indicate increasing their use of prefabrication and modular products. Module assembly yards... could lead to considerable cost savings, ranging from 6% to 30%. Besides material costs, modularization and prefabrication can also help reduce labor costs, ensure better design and quality control, and shorten the project schedule to ensure minimum budget overruns."

Deloitte, Engineering and Construction Industry Outlook, 2021

As a standard, MMC is helping enable the ongoing digital transformation in construction, real estate, and infrastructure moving smart construction forward in terms of logistics. In addition, this emergent technology offers builders and developers an important safety net for staying competitive, underscoring areas where off-site prefabrication or modular construction can occur.

The MMC Operational Framework

Modern Methods of Construction is an operational framework to define better and explain the possibilities in modern residential construction. With MMC, builders can employ a smart blend of strategy and technology to pre-manufacture and assemble buildings. The assembly processes can be carried out in off-site or near-site factories, consolidation centers, and the site itself.

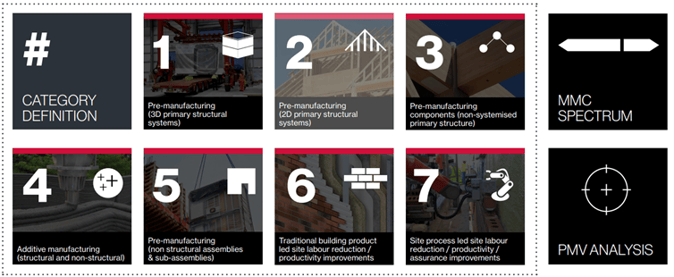

Source: Modern Methods of Construction; The Definition Framework

The general MMC framework defines seven areas within connected construction, or '7 MMC Categories,' ranging from pre to post-construction. Each category underscores the integration of approaches and the cost-effective potential for prefabrication and easier onsite assembly.

- Category 1: Pre-Manufacturing – 3D, which includes 3D renditions of primary structural systems such as the home or building's chassis. This entails off-site production of 3-dimensional units in controlled factory conditions.

- Category 2: Pre-Manufacturing – 2D primary structural systems. This uses flat panel units for walls, floors, and roofs; and more complex, prefabricated panels for windows and doors.

- Category 3: Pre-Manufacturing – Non-systemized structural components. This includes load-bearing beams, ring beams, staircases, trusses, and other superstructure elements.

- Category 4: Additive Manufacturing – Structural and non-structural. A remote, site-based category for the 3D printing of buildings and other onsite digital manufacturing techniques.

- Category 5: Pre-Manufacturing – Non-structural assemblies & sub-assemblies. A series of pre-manufacturing approaches that include whole bathroom and kitchen assemblies.

- Category 6: Traditional building, product-led site labor reduction/productivity improvements. This category emphasizes a pre-cut format for large wall configurations to make the traditional onsite assembly easier and reduce the required site labor.

- Category 7: Site process-led labor reduction/productivity improvements (and other lean construction techniques). This category includes all recent digital innovations in site-based construction, such as augmentation, BIM, drones, exoskeletons and other wearables.

MMC, in essence, looks for process efficiencies, which is why modular and off-site construction play such a key role. The types of residential buildings are also defined–from independent homes to high-rise apartments. Types of building materials are likewise classified to include mass engineered timber, light gauge steel, hot rolled steel, concrete, cement, and combinations of raw materials.

Amid the vast technological advancements of this digital age, MMC provides builders with a framework for materials and labor costs improvements—at every step. In addition, by outlining better processes, MMC helps define modern construction's improved modular abilities.

This lets builders cut costs without cutting corners and allows assiduous enterprises to take on more work without letting quality suffer.

MMC: Smart 'Connected Construction' Objectives

"The construction industry is likely to incorporate more digital technologies into key work streams in order to further enhance productivity, efficiency, and worker safety. These technologies include BIM and digital twins, which affect work from the design stage through material performance testing and remote project monitoring using sensors and drones. In fact, 76% of E&C executives in a Deloitte postelection poll indicated they are investing in connected technologies to address broad cost and margin challenges, and 24% are investing in drones and robotics at job sites to increase worker productivity and efficiency. These work changes make it important for E&C firms to start thinking of how roles and jobs will change to reflect the use of these new technologies."

Deloitte, Engineering and Construction Industry Outlook, 2021

As a working frame for modern, modular construction, MMC provides all those connected to construction with a codified framework that blends the vast improvements of digital innovation within modern manufacturing.

For construction as an industry, smart construction techniques can decrease labor costs, increase efficiencies, improve safety, and exponentially improve profits—all smart construction objectives.

The Future of Buildings

The scope of MMC and other BuildingSMART standards such as openBIM let homes and buildings be not just 'future-proofed' but future-ready. Their optimized design processes can address the most pressing challenges affecting construction, architecture and structural engineering today.

Smart, connected construction is the future of buildings, providing innovation and automation that allows for safe, successful industrialized construction. In terms of current construction trends, the most prevalent are onsite automation, off-site prefabrication, and digitally connected construction.

Various approaches exist along the MMC spectrum, including off-site, near-site and onsite pre-manufacturing. Within MMC's integrated innovations, the following six best practices have emerged to help define the future of buildings and smart construction.

01. Modular Construction; Offsite

Off-site construction refers to prefabricating the most elements possible for any home or building unit within an off-site, controlled environment: modular construction. This helps reduce onsite errors in building standard consistency, eliminates the risk of major tools or equipment losses off job sites, and dramatically reduces general costs for materials. According to McKinsey & Co., modular, off-site construction can also reduce average construction times by half.

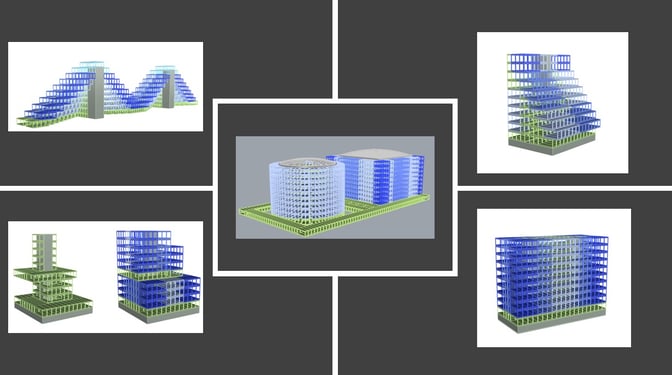

Source: Construct360; 3D Volumetric Construction Geometry Concept

As far as strategic implications for the construction industry, the Boston Consulting Group notes:

"The off-site revolution is sure to be highly disruptive. Construction sites will be less complex, need far fewer workers, and use different materials. Stakeholders all along the value chain will feel the impact, especially general contractors, equipment manufacturers, and producers of light-side building materials. Companies that join the revolution promptly could turn this disruption into a constructive opportunity."

BCG, The Offsite Revolution in Construction, 2019

02. OpenBIM: Business Information Modeling

OpenBIM refers to the collaborative process—among all participating agents—that supports shareable data and project management information for seamless interoperability by all participants in a project. BuildingSMART International is the home of openBIM standards, and Business Information Modeling (BIM) is at the heart of smart MMC designs.

As BuildingSMART International defines it, openBIM helps ensure:

- Interoperability among agents, developers and contractors.

- Open and neutral standards.

- Reliable data exchanges.

- Collaborative workflows with open, agile data formats.

- Flexibility in the use of individual technologies by all stakeholders.

- Sustainability is better safeguarded and standardized by long-term, interoperable data.

MMC relies on openBIM to keep construction connected, allowing data to be shared safely and securely by the responsible parties. Examples of recent BIM collaborations include:

- EGA used openBIM to design the 645,834square-foot Platinan building in Sweden. EGA also plans to design and build the Paris 2024 Olympics using BIM collaboration strategies.

- Norconsult, a Norwegian engineering and design firm, used BIM collaboration on the 19-kilometer E39 roadway in Norway, a project worth $500 million that linked the 2,000 people working on the same project.

03. Hybrid Construction

Hybrid construction allows for the best of both worlds. At its core, it helps blend best practices in traditional construction approaches with innovative, connected methods. By plugging in your construction project at its early phase—in pre-manufacturing—construction becomes easier and less costly. Fewer people are needed at the construction site. Quality is assured; at the best cost.

Taking a flexible hybrid approach can also help builders tailor the finer design details of a construction project, letting developers overcome most MMC barriers, such as design geometry flexibility, assemblies, logistics, contractual, financial, or even in terms of scalability.

Employing a hybrid blend of the best practices of traditional and modern construction can stabilize industrial construction and allow for continuous development.

Source: Construct360; Hybrid Construction - A New Way to Build

04. Design for Manufacturing & Assembly

- DfMA has a strategic approach to designing a building that considers manufacturing and assembly two steps of one continuous process. It aims to enhance construction and real estate development processes' performance, productivity, and standardization through technology solutions focused on industry needs.

When designing for manufacturing and assembly (DfMA), the costs and actions needed to assemble materials are reduced far in advance. Mass-producing parts and simplifying assembly are central aspects of DfMA. The five factors in Design for Manufacturing & Assembly are:

- Process

- Design

- Material

- Environment

- Compliance testing.

Since DfMA is pre-programmed into built environments, the end results are streamlined processes, reduced labor, and less waste. This, in turn, greatly improves time savings and overall sustainability.

05. Generative Design

Just one breakthrough digital technology in modern construction is Generative Design, an iterative design process that lets stakeholders explore even complex design issues automatically. Smart design-logic programs such as Generative Design can produce thousands of building design outputs or solutions that meet certain constraints and accommodate any operational parameters. The developer or designer teams then refine the program with each iteration to achieve their ideal design objectives.

Generative Design can help design for DfMA by taking the BIM model or 3D model further and creating a construction sequence. This involves many simulations to determine the best sequence of activities.

06. Built Environments & Ecosystem Services

In real estate development, a built environment refers to any building, park, neighborhood or green space supporting human activity. ScienceDirect studied the profound impact of smart construction on built environments, highlighting that ecosystem protections and intentionally designed stability and sustainability are now possible:

"The concept of ecosystem services can practically be applied to built environment design. A methodology for applying the ideas to designing whole buildings, neighborhoods, or urban areas... consider the built environment as a series of interdependent systems that interact with each other, local and more distant biological ecosystems, global climate, and human communities. Leveraging this understanding may be paramount to the evolution of built environments that have positive impacts on ecosystems rather than damaging ones."

ScienceDirect, Built Environment Design, 2017

The benefits of MMC in meeting smart construction objectives cannot be overstated. Ultimately, these benefits span from contractors to commercial developers to future home buyers and the environment at large.

Conscientious Construction: The Benefits of MMC

The goal of MMC is to provide the best building performance at an affordable cost. These benefits are achieved by optimizing the building process through a rigorous understanding of engineering, material science, and construction methods. The result is a more efficient and adaptable system to changing conditions than traditional construction methods.

Modern Methods of Construction such as connected processes, modular prefabrication, Hybrid Construction, 3D printing, Generative Design, DfMA, and more are the optimized processes marking the future of construction. In addition, unlimited designs in terms of aesthetics are the new normal.

Bashar, the founder of the Construct360 system, can help orchestrate your company's Digital Transformation and implementation of MMC, explaining which connected strategies should work best for you. Connectivity has come to construction. MMC is transforming boundaries. Is your team ready?

Modern Methods of Construction (MMC) is one of the change catalysts and enablers in the Construct360 practical approach to digital transformation in construction and real estate development companies.